In boardrooms and factories around the world, a once-obscure term has taken center stage: Scope 3 emissions. These are the indirect greenhouse gases up and down a company’s value chain – from the raw materials a firm buys (upstream) to the use and disposal of its products (downstream). For many businesses, Scope 3 is the hidden giant of their carbon footprint, often accounting for more than 70% of total emissions. Yet measuring and reducing these emissions has proven fiendishly complex, akin to untangling a global spiderweb of suppliers and processes. Enter Makersite, a startup deploying AI to map and manage supply chain sustainability.

Makersite’s recent €60 million Series B funding – a hefty raise in today’s climate tech landscape – signals not only investor confidence in the company, but also a broader maturation of tools to tackle Scope 3. In this feature, let’s explore how Makersite’s AI-powered platform is addressing Scope 3 emissions, why that matters, and how new policies are pushing companies to get a grip on their supply-chain carbon.

Table of Contents

ToggleThe Scope 3 Challenge: Big, Buried, and Binding

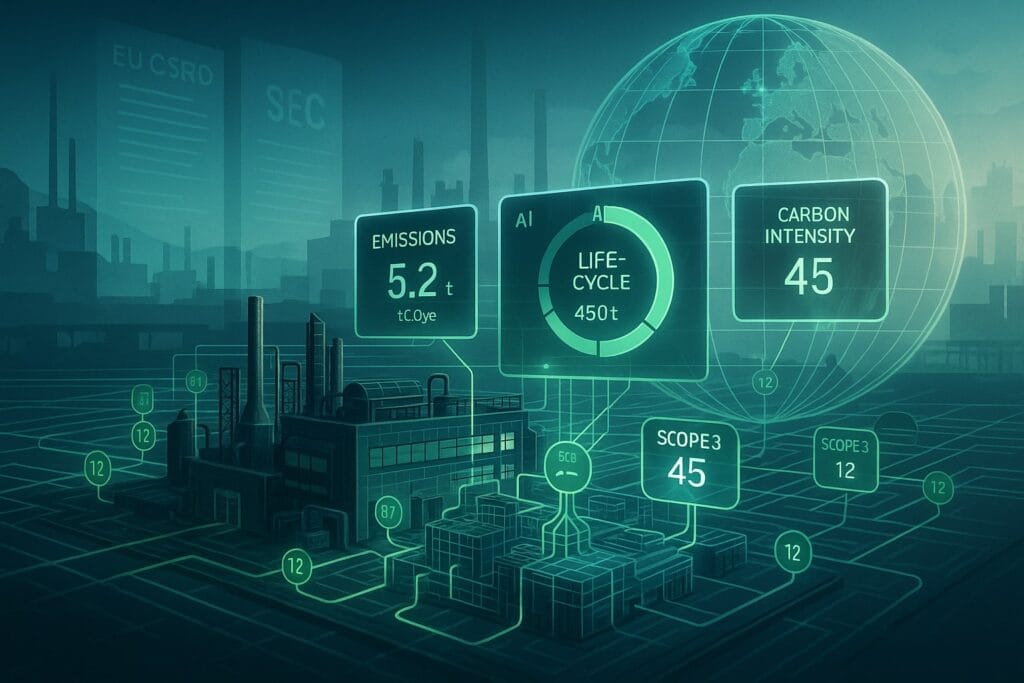

Scope 1 emissions are direct (like a company’s own factories or vehicles), Scope 2 are from purchased energy (electricity, steam), and Scope 3 covers everything else – the entire value chain. This could include emissions from making the components a company buys, employee travel, distribution logistics, product use (think of the fuel a car company’s vehicles burn), and product end-of-life. It’s no surprise that for most businesses, Scope 3 dwarfs their direct emissions. Deloitte estimates, and regulators cite, that over 70% of emissions for most companies are Scope 3. In sectors like consumer goods or tech, that number can be even higher – for example, a smartphone maker’s Scope 3 includes all the chip manufacturing, mining of metals, shipping, and consumer electricity use when charging devices.

The trouble is, unlike your own factory where you can measure smokestack outputs, Scope 3 data is scattered across countless suppliers and products. It’s data-intensive and fragmented. Many firms historically have had only a hazy idea of their full supply chain, let alone the carbon embedded in each part. But pressure is mounting from multiple directions to clarify and cut Scope 3:

- Regulation: The European Union’s new Corporate Sustainability Reporting Directive (CSRD) will require large companies to report Scope 1, 2, and 3 emissions, starting as soon as 2024/2025 for some. In the US, the SEC flirted with making Scope 3 disclosure mandatory; while it may scale back that rule under political pressure, states like California have passed laws that will force disclosure of Scope 3 by 2027 for companies doing business there. The direction is clear: globally, reporting Scope 3 is moving from voluntary to expected, and companies that ignore it risk non-compliance in key markets.

- Investors and ESG Goals: Many companies have set “net-zero” targets for 2040 or 2050 that explicitly include Scope 3. To be credible, they can’t cherry-pick only the easy internal reductions; they must engage suppliers to decarbonize. Investors, especially in Europe, are asking detailed questions about supply-chain emissions. A company that says it’s green but can’t back it up across Scope 3 might face accusations of greenwashing or see its cost of capital rise.

- Consumer and Brand Pressure: Large brand-name firms (think Apple, Unilever, automakers, fashion houses) have started to differentiate on sustainability of their products. Apple, for instance, touts how it’s driving down emissions in its supply chain by pushing suppliers to renewable energy. Such brands, in turn, cascade pressure onto their suppliers to provide carbon data and reduction plans. The entire chain reaction requires robust data handling and analysis.

All this makes Scope 3 management a huge emerging business need, and one not easily met by traditional enterprise software. You’re talking about handling life-cycle assessments (LCAs) of products, tracking thousands of components and materials, each with its own carbon profile. This is where AI and big data come in – precisely the realm Makersite operates in.

Makersite’s Solution: AI-Powered Product Lifecycle Intelligence

Makersite, founded in Stuttgart, Germany, has built a cloud-based platform that essentially creates a living digital model of a company’s products and supply chain, enriched with environmental and cost data. The platform ingests a company’s “fragmented and inconsistent” product data, cleans and structures it using artificial intelligence, and combines it with a vast proprietary database of materials and processes. This database knows, for example, the carbon footprint of producing a kilogram of aluminum in China vs. Europe, or the energy consumed in manufacturing a specific electronic component.

With this foundation, Makersite offers tools for different teams – design, procurement, sustainability – to analyze decisions in real time. For instance, an engineer can tweak a product’s design (swap one material for another) and instantly see how it changes the carbon footprint, cost, compliance, and even risk metrics. A procurement officer could plug in a potential new supplier and evaluate the trade-offs: maybe they’re cheaper but have higher emissions, or vice versa.

Crucially, Makersite automates Life Cycle Assessments (LCAs). LCAs are comprehensive analyses of a product’s environmental impact from cradle to grave. They used to be manual, consultant-driven exercises taking months for one product. Makersite’s AI can purportedly do this at scale, in minutes. A partnership announcement with Ahlstrom (a materials company) noted that Makersite enables automated LCAs “down to every purchased part and material,” providing granular Scope 3 tracking and reporting. That level of detail – being able to attribute emissions to each component – is gold for sustainability managers, because it shows exactly where hot spots are and where to prioritize improvements.

What about results? The platform is already used by major manufacturers like Microsoft, Cummins, Daikin, Barco, and Schneider Electric. Makersite proudly shares some outcomes: Microsoft used it to redesign its Surface Pro 10 laptop and cut that product’s carbon footprint by up to 28% in two years. That’s a substantial reduction, likely by substituting materials and tweaking design for recyclability or energy efficiency – changes informed by data. Schneider Electric, a giant in electrical equipment, used Makersite to implement eco-design across 300,000+ products (SKUs). This indicates the platform can handle very large catalogs, integrating with design software and PLM (Product Lifecycle Management) systems (indeed, Makersite even integrates with Autodesk’s CAD software for real-time eco-design feedback).

All these capabilities resonated with investors. The €60 million Series B in July 2025 was co-led by Lightrock and Partech, with participation from strategic backers like SE Ventures (Schneider Electric’s VC arm) and Hitachi Ventures. In a tough funding environment, such a raise stands out. Makersite’s CEO Neil D’Souza said it marks a “critical milestone” and noted it came despite “today’s uncertain economic and geopolitical environment” – underscoring how urgent and compelling the business case is. The funds will be used to scale the technology and team to meet growing demand from manufacturers seeking sustainable design decisions.

Data-Driven Decisions and AI’s Edge

Makersite’s approach exemplifies how AI can tackle Scope 3 where humans alone struggled. The platform’s AI doesn’t magically reduce carbon; what it does is automate data handling and provide decision support at a speed and comprehensiveness that was previously impossible. Some key advantages:

- Scope and Speed: Instead of analyzing one product at a time, companies can monitor thousands simultaneously. Makersite’s cloud can process “thousands of SKUs” rapidly, something that impressed investors as a “game-changer” for supply chain visibility. This means a company can baseline its entire portfolio’s footprint and then keep it updated dynamically – crucial as they make changes or as supplier data gets refreshed.

- Granularity: Because it goes part-by-part, Makersite helps avoid averages that obscure insight. For example, rather than saying “our supply chain emitted X million tons CO₂,” a company can pinpoint which components or suppliers contribute the most. Perhaps that one exotic alloy in a device is causing outsized emissions due to an energy-intensive refining process – Makersite would flag it. This granularity is what turns reporting into actionable strategy.

- Trade-off analysis: Sustainability doesn’t happen in a vacuum – there are cost and performance trade-offs. The platform explicitly treats sustainability as a “balanced trade-off between cost, safety, and environmental performance”. That’s appealing to business managers who need to ensure any green improvements also make economic sense. For instance, if a lower-carbon material is exorbitantly expensive or fails safety specs, the AI will show that. Conversely, it might find “win-wins” – e.g., a recycled material that is cheaper and cuts emissions. Those opportunities are the holy grail, and AI is adept at sifting through complex data to find them.

- Compliance and Risk: Scope 3 isn’t just about carbon; it intersects with regulatory compliance (e.g. EU’s Carbon Border Adjustment Mechanism – CBAM – will penalize carbon-intensive imports) and supply chain risk (geopolitical, resource scarcity). Makersite’s data covers regulatory status and risk metrics too, meaning one platform can tell you if a certain chemical in your product might be banned soon or if a supply chain is overly dependent on a region. This holistic view is increasingly valued – companies want to solve for sustainability in tandem with resilience.

An example of regulatory tie-in: CBAM (mentioned on Makersite’s site) will require importers to report embedded emissions of certain products and eventually pay tariffs on them. A tool that calculates those embedded emissions accurately becomes essential for compliance and cost planning.

Policy Push: From Reporting to Action

As noted, policy developments are huge drivers in this space. Let’s put Makersite’s rise in context of the policy climate:

- The EU CSRD and taxonomy regulations effectively force companies to quantify Scope 3 or explain why they can’t. That’s a big motivation to invest in tools like Makersite. Europe’s large companies (and many multinationals have EU presence, so they’re affected) are right now scrambling to get data systems in place to meet new reporting standards.

- In the U.S., while the SEC’s climate rule is uncertain (it dropped explicit Scope 3 requirements for now after lobbying), the writing is on the wall that investors expect full emissions disclosure. Plus, California’s law (SB 253) will rope in big companies to disclose Scope 3 from 2027. So even without federal SEC rules, many U.S. companies will need to measure Scope 3 to comply with state law or voluntary standards like the ISSB (International Sustainability Standards Board) guidelines, which also consider Scope 3 best practice.

- Government and NGO procurement standards are emerging that favor companies who know and manage their supply chain footprint. Think of defense or infrastructure contracts – in Europe, bidders might need to report emissions. Congressman Salud Carbajal’s efforts in the U.S. defense arena, for example, compel the Pentagon to consider communities affected by launch noise (another supply-chain externality). Similarly, one could envision future requirements for defense suppliers to account for carbon in their manufacturing. Makersite actually ties into defense indirectly – it’s not just consumer products; any complex manufacturing (including aerospace, defense) could use its analysis.

The bottom line: a perfect storm of pressures – regulatory, financial, societal – has made Scope 3 a board-level issue. This is why Makersite’s Series B was oversubscribed while some other tech startups struggle. It sits at the nexus of climate action and corporate need, offering a solution to a problem companies must solve. As Lightrock’s investing partner put it, Makersite is poised as a “future leader” helping firms navigate complex challenges with measurable impact.

Impact and the Road Ahead

The fresh funding will let Makersite enhance its platform and scale globally. This likely means more integrations (with ERP systems, CAD tools, procurement software), expanding its massive data libraries, and improving the AI’s speed and insights. As more companies use the platform, a beneficial cycle emerges: more data flows in, which can improve benchmarks and machine learning models, making predictions and gap-filling more accurate.

One can envision Makersite or its ilk becoming as standard in manufacturing as CAD software or ERP systems. A decade ago, “sustainability software” was niche; now it’s moving to must-have. There’s competition, of course: startups like Persefoni and Watershed focus on carbon accounting for corporate footprints (though often more on the tracking and reporting side than the detailed product design side where Makersite shines). Big software firms like SAP have sustainability modules. But Makersite’s deep focus on product-level analysis with AI gives it a lead in a very specialized and critical area.

We should also consider challenges: Getting quality data from suppliers remains tough. AI can estimate or use industry averages where data is missing, but true accuracy needs suppliers to actively share info. Platforms often rely on a mix of primary data and secondary databases. Part of Makersite’s mission likely involves nudging suppliers into the fold – possibly via its customers, who will ask their suppliers to use Makersite’s interfaces to input data. In some cases, regulations will push suppliers to provide data (e.g., EU requiring carbon footprint info for certain materials). A risk is if suppliers are reluctant or data is unreliable, the outputs may have uncertainty. But here AI can also help by cross-verifying and flagging anomalies (e.g., if one supplier’s reported numbers look way off the benchmark).

Another challenge is moving from insight to action. It’s one thing to identify that 80% of a product’s emissions come from, say, the aluminum housing. It’s another to actually reduce that: you might need to find recycled aluminum, or redesign the housing, or work with that supplier on renewable energy. Makersite provides the roadmap and “what-if” scenarios – but companies must still do the heavy lifting of engaging suppliers and redesigning products. The hope is that by making the impacts clear and quantifiable (in carbon and cost terms), it catalyzes action that otherwise wouldn’t happen due to lack of visibility.

Encouragingly, we see more firms setting concrete Scope 3 reduction targets. For example, auto companies are pushing steel suppliers for low-carbon steel, fashion brands are investing in sustainable materials. All this will rely on data systems to track progress. And when they implement changes, they’ll use platforms like Makersite to validate the improvement – did switching to Supplier B actually cut emissions as expected? The platform’s reporting tools help communicate those metrics to stakeholders. In essence, AI platforms become the backbone of continuous improvement loops in sustainability.

Looking forward, we might imagine AI-driven optimization: not just analyzing decisions humans suggest, but AI proactively recommending design or sourcing changes for lower footprint. Makersite is already partway there – users can query, “how do I reduce cost and carbon for this product?” and the system could highlight certain components or suppliers to change. As the datasets grow, the AI could even suggest novel materials or alternative designs by learning from across industries. (E.g., “We noticed companies using X polymer instead of Y in similar products cut emissions 30% – consider that substitution.”) This kind of cross-pollination insight is only possible when you aggregate lots of data, which Makersite does.

Finally, consider the scale of potential impact. Manufacturing is responsible for ~19% of global emissions. Tackling Scope 3 in manufacturing supply chains is tackling a big wedge of the climate problem. If tools like Makersite help hundreds of manufacturers each cut a quarter of their product footprints (recall Microsoft’s 28% reduction on Surface Pro 10), the cumulative effect is enormous. It also addresses resource use and waste, since often a lower-carbon design is also more material-efficient and compliant with regulations (no hazardous substances, etc.).

The Series B announcement aptly noted that manufacturers face “mounting pressure” to address emissions as they also restructure supply networks for resilience. The combination of COVID-19 supply shocks and climate urgency created a moment where companies are re-thinking supply chains fundamentally. Many are re-shoring or diversifying suppliers for resilience; at the same time, they can choose greener suppliers or demand cleaner processes. In that sense, AI for Scope 3 is part of a broader trend of smart supply chain management, where sustainability, risk, and efficiency are jointly optimized.

In conclusion, Makersite’s big funding round and growing adoption show that climate tech is getting smart and specific. This isn’t about vague carbon offsets or pledges – it’s about granular, data-driven changes to how products are made. It’s a shift from counting carbon to actually engineering it out of products. As companies integrate these AI tools, we may finally see the needle move on the hardest part of decarbonization: the deep supply chain. Scope 3 may be complex, but it’s no longer a black box. With AI illumination, what was once invisible becomes actionable – and businesses that embrace that will not only stay ahead of regulations but likely cut costs and innovate better products in the process. That’s a story of climate action that even the most hard-nosed CFO can get behind, and it bodes well for the future of sustainable manufacturing.